Conveyor Belts - Complete Range

We specialize in the manufacturing of diverse range of conveyor belts that find applications across various industries including agriculture, aviation, cement, chemical, ginning, glass, construction, steel and iron, mining, foundries, and more. below are the complete list of conveyor belts manufactured by Continental Belting Private Limited.

Detailed Information

All Types of Conveyor Belts

1. General Purpose Conveyor Belt

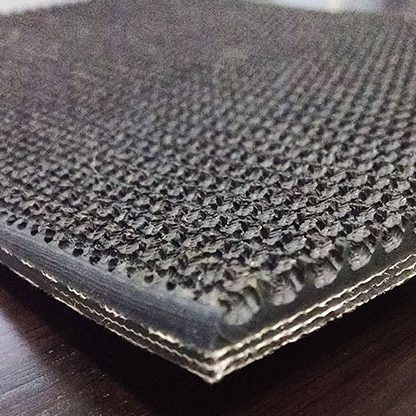

Continental Belting Pvt. Ltd. manufactures a wide range of rubber conveyor belts for various sectors, such as mining, coal handling, stone crushers & quarries, ports, etc. industries where there is a requirement for a robust conveyor belt, having excellent cut, abrasion and gouge resistance. These belts can be supplied in different carcasses, namely, cotton, Nylon-Nylon, Polyester-Nylon (EP), Aramid & Steel Cord.

Besides the conventional M24 Grade Belting, which is a universally accepted product, our EMERY Grade Belting, having 40% superior Abrasion Resistance, is popular, and well suited for applications, where highly abrasive materials are handled, in the quarry and mining applications. For handling metal scrap, or any other applications, where longitudinal cutting of the belt is a challenge, we have on offer, fabric belts with transverse steel breakers, from our Tear-Guard range, which has proven to be 96% effective in preventing longitudinal cuts.

We have the ability to manufacture conveyor belts for your unique needs, so please brief our sales experts of your concerns, and we shall tailor a belt, to suite your unique requirements.

General Duty Conveyor Belts are used in various industries, such as Glass Industry, Ginning Industry, Mining Industry, Ports, Agro Industry, Airline Industry, Cement Industry, Chemical / Fertilizer Industry, Coking Plants, Foundries, Iron and Steel Industry, Infrastructure / Construction Industry, Power Plants, Smelters etc.

2. Heat Resistant Conveyor Belts

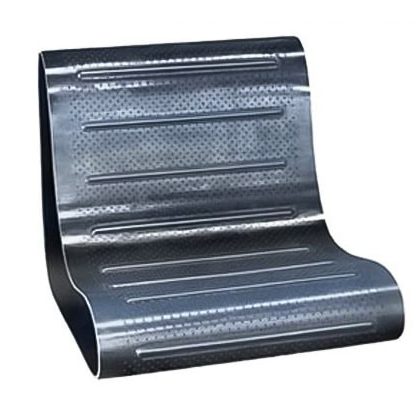

In contrast to ambient applications, high-temperature environments present a more significant challenge due to the reduced life expectancy of belts and heightened maintenance issues, particularly related to cracks. This becomes even more critical when handling fine powdered materials, leading to substantial material spillage. Recognizing the formidable challenges faced by maintenance managers, Continental Belting has undertaken the development of fail-proof Heat Resistant Conveyor Belts.

Our successful efforts have resulted in a comprehensive range, spanning temperatures from 100°C to 350°C, with specialized variants designed to meet specific application needs. These include belts with Heat & Oil Resistance as well as Heat & Fire Resistance capabilities. Whatever your application may be, we have a tailored solution to meet your unique requirements.

A prevalent issue in industries dealing with pulverized materials is heat cracking, leading to spillage and environmental pollution caused by material entrapment in belt cracks. In response to this concern, we have introduced the Pyroshield range, a specialist solution with low or no cracks and excellent aging characteristics.

Our focus extends to industries and applications involving Sinter, Coking, Foundry Sand, Alumina, Sponge iron, and more.

If you’re experiencing challenges related to high-temperature applications, we invite you to share your specific concerns. Be assured of positive results and feel free to reach out to us at +91 8828820325 for personalized assistance.