M-24, N-17, Emery Grade

General Purpose Conveyor Belts

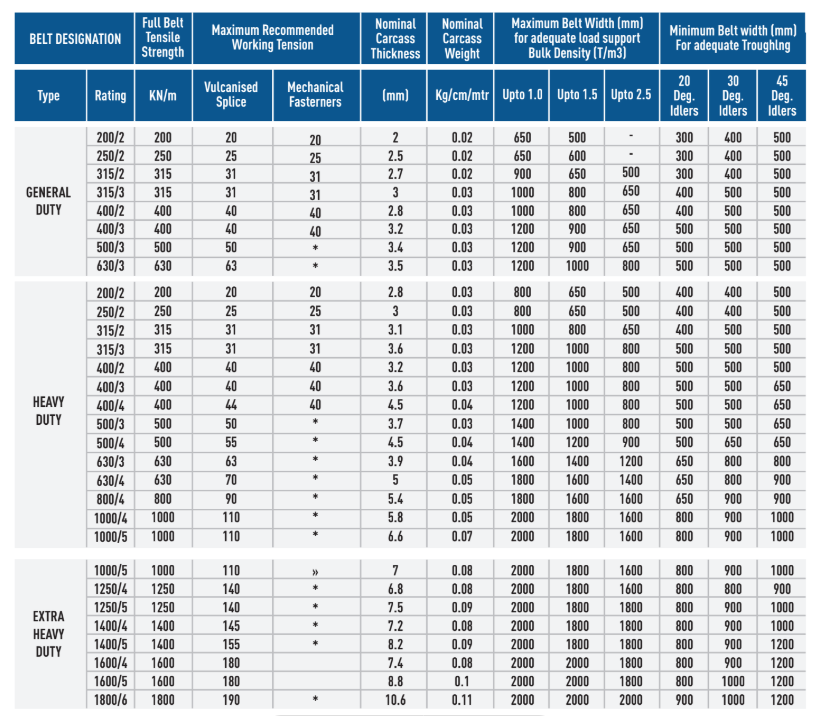

Continental Belting Pvt. Ltd. manufactures a wide range of rubber conveyor belts for various sectors, such as mining, coal handling, stone crushers & quarries, ports, etc. industries where there is a requirement for a robust conveyor belt, having excellent cut, abrasion and gouge resistance. These belts can be supplied in different carcasses, namely, cotton, Nylon-Nylon, Polyester-Nylon (EP), Aramid & Steel Cord.

We are the leading General Purpose Conveyor Belt Manufacturers In India.

Besides the conventional M24 Grade Conveyor Belt, which is a universally accepted product, our EMERY Grade Belt with 40% superior Abrasion Resistance, is well suited for applications where highly abrasive materials are handled, in the quarry and mining applications for handling metal scrap, etc. Where longitudinal cutting of the belt is a challenge. We have on offer, fabric belts with transverse steel breakers from our Tear-Guard range, which has proven to be 96% effective in preventing longitudinal cuts.

We have the ability to manufacture conveyor belts for your unique needs, so please brief our sales experts of your concerns, and we shall tailor a belt, to suite your unique requirements.

Since 1984,

Operating in India

Features

Anti-tear and rip resistant qualities. Special Steel wefts with high elongation and tensile strength properties arranged at a nominal pitch.

- Manufactured to DIN standards.

- Exceptional fastener-holding ability if required.

- Longer service life under heavy-duty applications.

- To break the ripping momentum; limiting any longitudinal cutting and tearing

- Pulley system modifications not required; transversal steel/fabric weft has no influence.

- Superior carcass protection through greater impact energy distribution across the belt width.

Call Us Now

(+91) 8828229262

Applications of General Purpose Conveyor Belt

Using only the greatest raw materials, we create products that serve a variety of industries.

- Slag conveyors

- Coking conveyors

- Broken glass / cullet

- Coal handling plants

- Cement, concrete plants

- Sand, gravel, stone industry

- Road construction machinery

- Timber industry and sawmills

- Power plants , garbage incineration plants

- Silica sand or materials containing silica sand

- Recycling, compost industry, mineral processing plants

Continental Belting Pvt. Ltd. manufactures rubber conveyor belts that not only meet but exceed the minimum standards set by IS 1891 in several key performance areas, Below is a comparative overview of our M24 Grade Belts :

This comparison highlights Continental Belting’s intent to delivering conveyor belts with superior performance characteristics, ensuring reliability and longevity in various industrial applications.