Belting Solution For Steep-Inclined Conveying!

Chevron Conveyor Belt

The rubber cleats on Chevron conveyor belt get vulcanized onto the top cover of the belt during the manufacturing process. Profiles manufactured of extremely abrasion-resistant rubber types are available in 45 to 60 Shore hardness compounds. It offers a smooth ride across return idlers thanks to the pitch between two cleats. As a result, we are the most reliable Chevron Conveyor Belt Manufacturers.

Since 1984,

Operating in India

Features

Anti-tear and rip resistant qualities without any equivalent in conventional fabric conveyor belts. Special Steel wefts with high elongation and tensile strength properties arranged at a nominal pitch.

- A large range of designs and patterns available

- Excellent choice for high capacity conveying at steep angles to prevent load slip or product roll back

- Cleats integrally moulded with the top cover rubber preventing separation from the belt

- Cleats with high abrasion resistance and elastic rubber compounds for flexibility

- Various cleat heights and widths available depending on the application requirements

- Chevron belt manufactures, in all cover grades, viz. Abrasion Resistant M24, HR, OR, FR, White Hygienic, etc.

- Unique Pattern design ensures, that, the belt has a smooth run on conventional return idlers, so no modification of the conveyor required. A smooth transition from a conventional flat belt to a Chevron belt can be implemented.

Call Us Now

(+91) 8369780337

Applications of Chevron Conveyor Belt

Using only the greatest raw materials, we create products that serve a variety of industries.

- Wood Chips

- Sand and Gravel

- Heavy Duty Scrap Metal

- Minerals - Coal and Ore

- Materials - Fine Coal and Grains

- Waste and Recycling Plants

- Road Construction & Crushing Industries

- Bagged Materials

- Steel Pellets

Continental Belting Pvt. Ltd. manufactures rubber conveyor belts that not only meet but exceed the minimum standards set by IS 1891 in several key performance areas, Below is a comparative overview of our M24 Grade Belts :

This comparison highlights Continental Belting’s intent to delivering conveyor belts with superior performance characteristics, ensuring reliability and longevity in various industrial applications.

Effective Solutions

We work with your company to identify your requirements depending on your application and thus initiate our manufacturing, supplying, and exporting process.

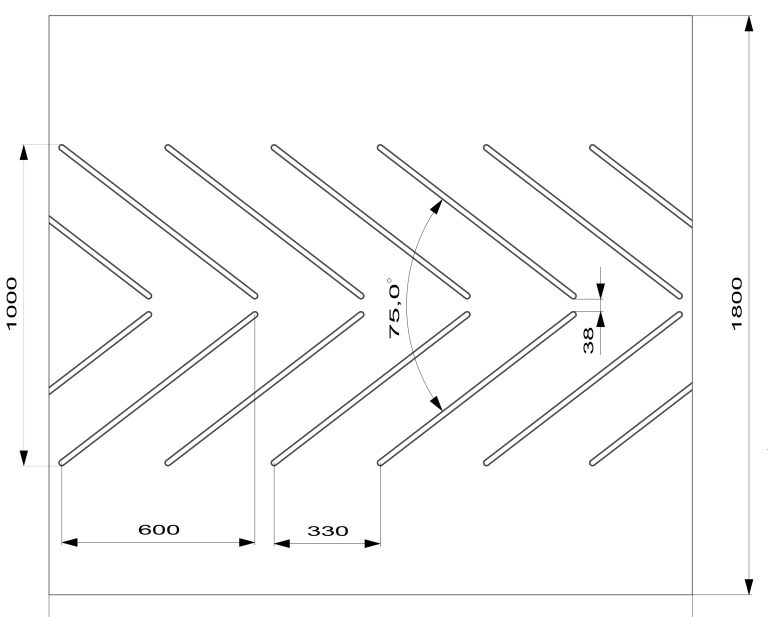

Chevron Open V25/1000

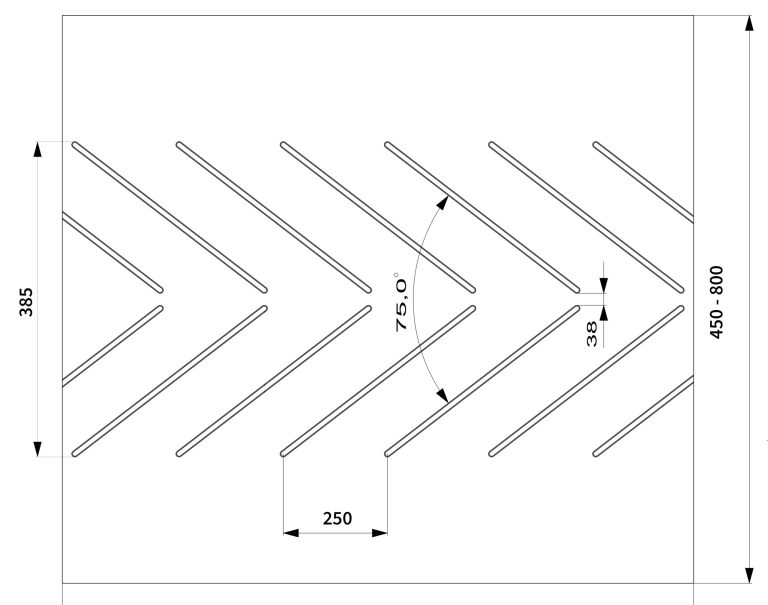

OPEN V15 - 385